Alliances between vehicle manufacturers is not something new; Since the beginning of automotive history we find a large number of strategic partnership between different companies. In today’s article we talk about the very popular R9M engine, developed by Nissan-Renault and Mercedes, and we get an in-depth understanding to its operation.

R9M engine

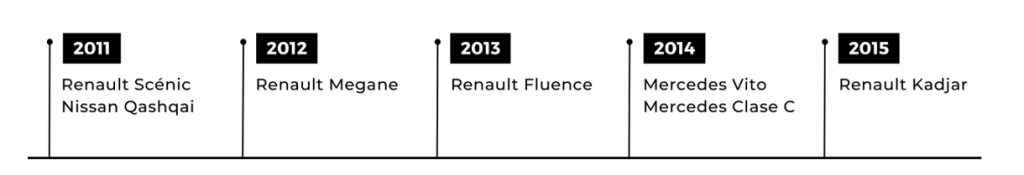

The Energy dCi 130 engine is an engine that was developed by the consolidated work between Renault, Nissan, and Mercedes, on a 1.6 dCi version in 2011 as a result of the need for improvements on the predecessor 1.9 dCi engine.

With a variable geometry turbocharger or a high-pressure EGR valve, this engine, known as ‘R9M’, rapidly found its way into a wide range of applications, becoming the new popular engine thanks to its 130 HP and innovative technology.

Later, and after its good performance, were launched on new versions as 160 and 145HP.

The main improvement of this engine versus its predecessor, the 1.9 Dci, was the reduction on consumption and emissions.

Proof of this are the following examples:

- On the Renault Scenic the engine consumption is 4,5 l/100km whereas its predecessor on the 1.9 DCI was 5.4L.

- Regarding CO2 emissions, the R9M data is 117g/km de CO2 compared to 149g/km for 1.9 Dci.

How they manage to do so?

These improvements in fuel economy and emissions savings over other engines are achieved through four key factors in the configuration and design of this engine:

- The concept of variable vane oil pump able to adjust the oil flow and pressure according to the engine needs.

- Variable spiral air inlet admission that helps the engine to optimize the air/fuel mixture.

- Optimized thermal management with an internal valve capable of managing the coolant through the engine just when is needed.

- An EGR exhaust gas recirculation system. A low-pressure EGR valve directs exhaust gases through a filter before entering them back into the intake.

What can go wrong then? R9M engine issues

Previous Renault engines are known to have struggled on timing belt system, putting too much stress on the tensioner and even on the water pump bearing. The idea to use a timing chain kit was the best option, but this design presents a challenge.

The inlet an exhaust cams are connected through a cog gear mechanism, the teeth are no helicoidal as we can see in most recent Mercedes engines. Through the usage and on some occasions an incorrect maintenance, a clearance is generated between the gears.

This clearance generated noise and since the cam timing chain sprocket is mounted directly on top of one of the gears, the vibrations are transmitted to the timing chain kit mechanism. As result a premature wear between the sprocket and chain happens.

New DOLZ Timing Chain Kits: SKCR150 & SKCR151

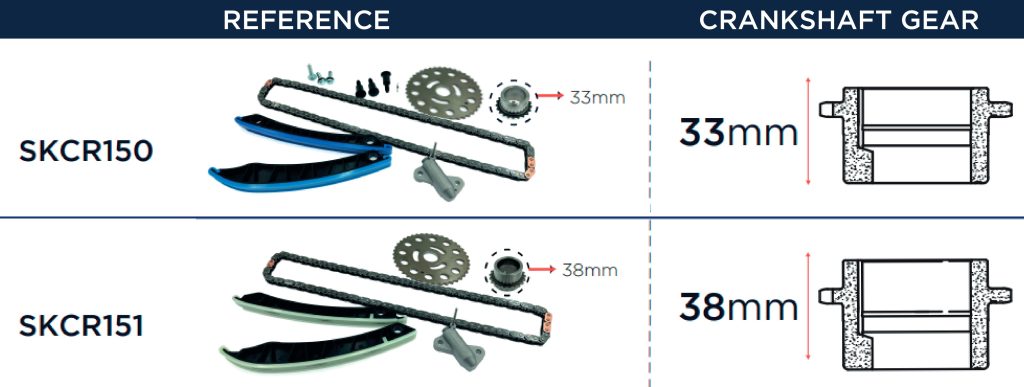

Dolz is proud of launching these 2 kits with both versions available at OE level, which the reinforced material used on the sprocket and the latest version of the chain, will help our customer to keep driving more many years to come these iconic engines.

Both references differ exclusively in the design of the crankshaft sprocket, therefore, depending on its application, its dimensions will be 33mm for the SKCR150 reference and 38mm for the SKCR151 kit.

Thanks to the experience and its commitment, Dolz products have uncompromising quality, with the latest technological innovation and 100% tested.

Both part numbers are already available for workshops and distributors in the different electronic catalogs such as TecDoc and Sofinn.

If you require any further information, don’t hesitate to contact us as we’ll be glad to be of help.

Keep reading: Dolz/GGT New-to-Range. +21 new references!