Called front-end accessory drive system (or FEAD for short) its efficient distribution of power render it an essential component of a vehicle’s flawless operation and shouldn’t be confused with the timing belt which serves a completely different purpose.

Nowadays, new environmental regulations and higher electrical demand push manufacturers to reduce the power losses of their engines, generating a challenge to the FEAD system functioning.

Specifically, the car’s auxiliary drive belt is a component that is often overlooked as a source of mechanical issues in aging vehicles. But even if an old serpentine belt looks good, the truth is that it has a limited lifespan, so replacing it with a new belt can save you money in the long run. Thankfully, there are ways to improve the lifespan of the FEAD system.

Read about these methods of improvement below.

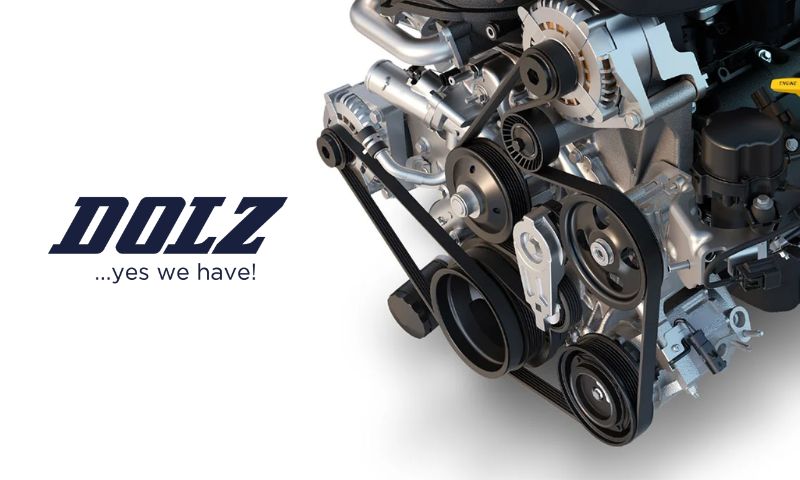

Understanding the front-end accessory drive components

In automotive accessory belt drive systems, the crankshaft delivers mechanical power to critical engine accessories. That is the alternator, the power steering pump, the A/C compressor, and (sometimes) the water pump. As the belt needs to be really quite long you’re also likely to find an idler pulley, and/or a tensioner pulley in the mix.

- The poly-V belt is a composite made of elastomeric material layers, generally EPDM rubber, and a cord layer (fiber) and is used to drive the alternator and water pump by transmitting power from crankshaft pulley.

- Idler-pulleys are often used in this type of transmission to increase the wrap angle around the pulleys and are available in various shapes and sizes depending on the application.

- The pulley systems on modern engines typically use an automatic tensioner. The tensioner is a self-tensioning device that applies tension to the aux belt, helping keep it taught in the various operating conditions. Also preventing it from slipping or jumping off other components.

Auxiliary System Maintenance Tips

Proper front-end accessory drive maintenance is important to keep equipment running as efficiently as possible and to keep the various drive components from wearing prematurely. Here are some maintenance tips to ensure your system is in tip top condition:

- As for when you need to replace these belts, there’s no hard-and-fast rule. It varies depending on the vehicle and the conditions under which you drive. But formost cars, it’s recommended that you get the serpentine belt inspected once your car reaches 60K miles. So, perform maintenance as scheduled with the vehicle manufacturer and replace components before they wear out and cause further damage to the vehicle.

- Inspect the system to make sure all components are aligned. Use a laser alignment to ensure proper alignment.

- Inspect belt and pulleys for signs of wear. Checking for cracks, fraying, splits or worn spots. Also, listen for unusual noises such as a chirping or squealing sound.

- The tension of your serpentine belt is a critical factor in its performance and longevity. So, check the belt tension: it should be tight, with little or no give.

- Replace all FEAD components at the same time. This helps prevent comebacks, reduces noise issues, and enhances overall system performance. In fact, replacing the belt alone rarely solves the customer complaint.

With these easy tips, you can maximize the lifespan and performance of your auxiliary drive system. Don’t forget to consult your vehicle’s manual or seek professional advice for specific maintenance procedures.

As we have pointed out on previous occasions the most obvious symptoms of failure of the auxiliary belt system are steering hardening, vehicle battery or A/C failure or humming in the engine. For this reason, it is important that you must be able to identify the signs of a defective FEAD system due to its importance to the functioning and comfort of your car.

Related content: Auxiliary Drive Belt Tensioner for hybrid applications: DOLZ SKD250A

DOLZ Auxiliary Drive Kits

In order to make your life easier and to secure effortless replacements, each OE-quality auxiliary drive belt kit includes all application-specific components needed to complete a front-end accessory drive (FEAD) system repair. All in one single package:

- V-ribbed belt or auxiliary drive belt

- Pulleys and idlers

- Drive tensioners

- All the necessary accessories when needed.

If you require any further information on any of our product lines, receive commercial information or technical product specifications (including assembly notes) don’t hesitate to contact us as we’ll be glad to be of help.