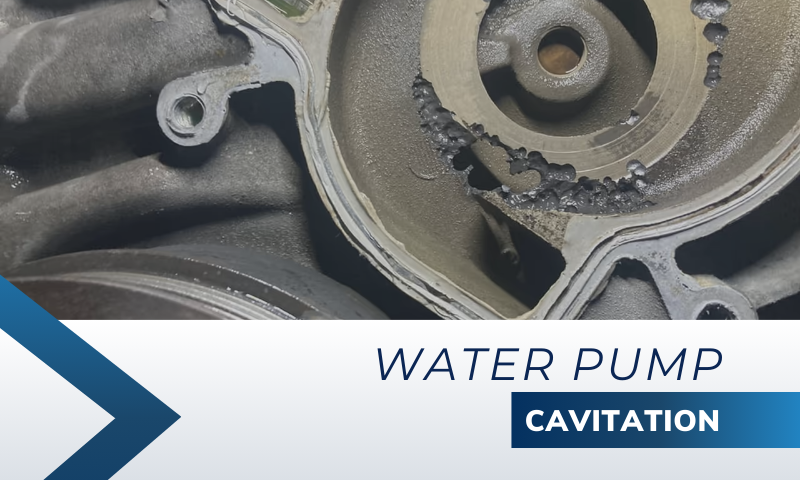

Sometimes, during the water pump replacement, most mechanics find unusual scenarios such as the phenomenon of cavitation in the water pump. Specifically in the pump impeller.

In today’s article we explore the effects of pump impeller cavitation, and we also talk about the preventive measures that must be taken against this phenomenon and keep water pump in safe working condition.

The impact pump impeller cavitation

Pump impellers can tolerate a small amount of low energy cavitation without damage or significant reduction in life. The more intense the cavitation is, the quicker the water pump will be damaged.

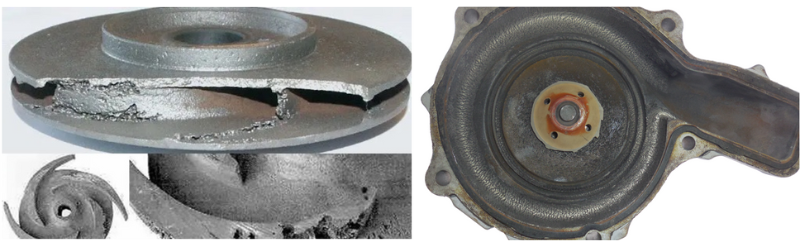

In other words, cavitation causes pump performance deterioration, mechanical damage and erosion to the impeller as we can see in the following pictures (which can ultimately lead to pump failure).

The impeller is one of the key components of a water pump, essential for its efficiency and performance within the cooling circuit.

Keep reading: The importance of the water pump impeller

There is also the possibility of material release from the blades and even from the volute as well.

Under normal conditions, the impeller of a water pump do not show any deterioration and can only be encrusted with settled solids build-up on their blades.

Are there any signs of failure on the vehicle?

The answer is Yes, but we must address a few explanations first to understand what cavitation is and how it affects the operation of the cooling system.

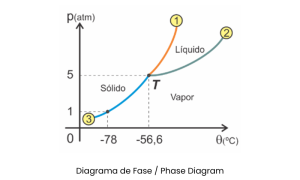

The first issue to highlight is that any liquid and in general any material can exist in liquid, solid or gaseous state. In this case, the coolant state basically will depend on two parameters: pressure and temperature (during a phase-change process, both are dependent properties).

By decreasing the pressure of the coolant liquid to the same temperature, the liquid will turn into a vapor state. And vice versa, if we increase the pressure of a gas, it will become a solid.

The coolant circulates throughout the engine coolant circuit. This is a closed-loop and sealed system by the radiator cap or the expansion tank cap.

When we start the vehicle’s engine, the heat from the turbocharger and the engine cylinder head heats up the coolant and thus the pressure in the circuit increases. At that moment, two situations can occur:

- If the pressure of 1.0 bar is exceeded, the circuit pressure is relieved by opening momentarily.

- If the cap does not close the cooling circuit, the pressure automatically decreases (being atmospheric).

How is cavitation done?

Cavitation in the water pump happens in two phases. Initially, the coolant exposed to high temperatures begins to evaporate and forms the bubbles that constantly burst into the coolant that circulates through the water pump.

The process that initiates cavitation is a sudden pressure drop and/or coolant temperature increase, that is: rapid changes in pressure. This occurs when the coolant liquid passes from the suction side of the impeller, and the pressure decreases, the liquid molecules turn to vapor. But when the impeller increases the speed and transfers the energy of that vapor, this vapor becomes coolant liquid again. Ejecting (in an explosive way) bubbles that collapse, creating an intense shockwave that hits the impeller and creates pump vibration and mechanical damage as we have observed previously.

How to prevent pump cavitation?

By preventing cavitation, you will significantly increase the efficiency and lifespan of your water pump. Among the main causes of cavitation in cooling systems is the incorrect use of coolant.

To avoid it, it is important to maintain the appropriate coolant fluid level, as well as always use the coolant fluid recommended by the car manufacturer. It is also important to inspect the condition of the water pump or thermostat through preventative maintenance.

Related content: Coolant guide. Suitable coolants for the vehicle.

At Dolz we also recommend that, if you see the impeller has material loosening, do not replace just the water pump, replace also the radiator cap or the expansion tank cap in the same operation.

In conclusion, good design to avoid cavitation is always the best option. Dolz water pumps have excellent certified quality, equivalent to the original equipment manufacturers. Our commitment to Quality, Service and Innovation has been amply demonstrated for decades, been recognized as one of the leaders in the manufacture of water pumps in Europe.

If you need any help identifying which components you need for your system or further information about Dolz’s water pumps for passenger cars, heavy duty or commercial vehicles, don’t hesitate to contact us at dolz@idolz.com.

Don’t compromise on quality!