What is cavitation?

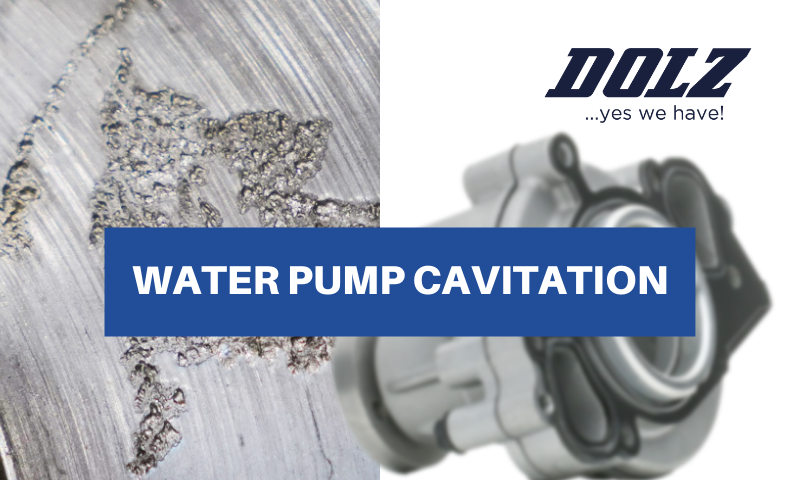

Bubbles form during cavitation in the cooling system. As the pressure in the pump increases, those bubbles collapse in the form of an implosion. This is a phenomenon that occurs at very high rpm and is one of the main problems that can cause a water pump to fail.

But what causes cavitation?

When the pressure within the system drops or is not evenly distributed throughout the circuit, the vibration is subject to cavitation (formation of steam).

Cavitation in the water pump happens in two phases. Initially, the coolant exposed to high temperatures begins to evaporate and forms the bubbles that constantly burst into the coolant that circulates through the water pump.

Once the vapor bubbles are formed and with the pressure recovered, it is when they collapse creating an intense shock wave damaging the surface of the water pump and the rest of the components of the cooling system where this phenomenon is caused.

The impact of cavitation on a water pump

Cavitation in water pumps is not caused by the water pump itself, it only receives damage, it does not generate it.

The main cause is in the coolant that circulates through the system at a high speed and is exposed to intense pressure variations. The area of the pump with the lowest pressure is the inlet section, the suction port, just before the impeller blades, and this is where cavitation occurs.

Another cause is found in problems of collapse or restriction of the flow of the system itself. For example, a radiator hose that isn’t working as it should interrupt the flow of coolant and cause hot spots that will cause the system pressure to rise until bubbles form.

How to prevent cavitation problems

The state condition of the coolant undoubtedly has a direct relationship with the water pump cavitation. At Dolz we recommend some prevention measures that will help you avoid having to deal with cavitation problems:

- Use manufacturer-recommended antifreeze.

- Thorough inspection of the cooling circuit for leaks or signs of failure.

- Carry out preventive maintenance ensuring the proper functioning of the cooling circuit.

- Replace parts only with those that meet OE specifications.

Keep reading… How to detect cooling circuit problems

Dolz, leading manufacturer of water pumps

Dolz, the most reliable and durable water pumps on the market. All our range has the ISO 9001:20015 certification, which means quality 100% tested. Regarding the quality control phases, the tightness test using a calibrated leak instrument to verify the air pressure drop is within the defined tolerances and thus prevent cavitation.

A process as simple as it is fundamental and for which, among many other factors, DOLZ water pumps are the pumps with the highest quality on the market.

We manufacture more than 5.5 million units per year over a range which comprises:

- Water pumps for passenger cars

- Water pumps for industrial vehicles

- Auxiliary electric water pumps

- Variable water pumps

- Electric water pumps

Good design to avoid cavitation is always the best option!

Get in touch to learn more about our range of water pumps and other Dolz product lines.