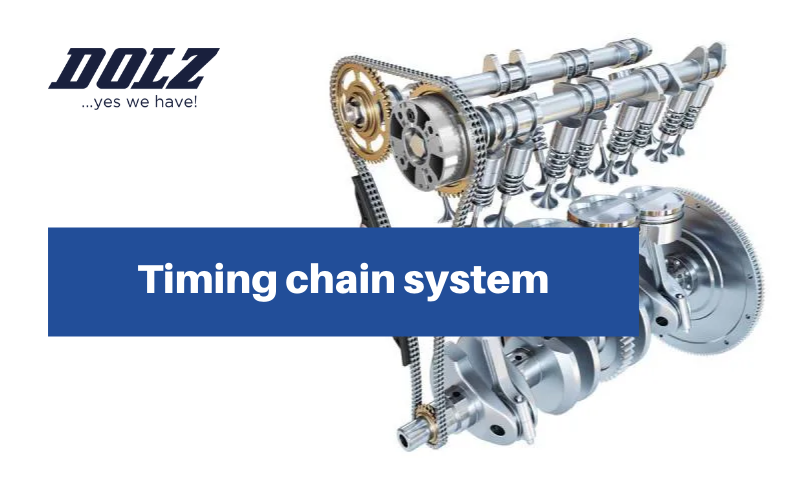

How engine timing chain systems works?

The vehicle’s timing chain determines the performance of any existing automobile. Being responsible for the engine’s correct functioning. By keeping the camshaft(s) and crankshaft in sync, they control how the engine runs, the power it delivers, the fuel it consumes and the emissions it creates.

Technological advancements have enabled the production of more durable alternatives to timing belts. The chains being increasingly silent and lighter.

These are currently gaining ground in all types of modern applications. Their purpose is no different, however, they no longer require regular maintenance and there is no need for timing chain replacement either.

As a power transmission system, chain can transmit high torque loads in a compact package. In a fraction of a second, a timing chain keeps the fuel injectors, air intake and pistons synchronized.

When a piston moves downwards, air and fuel should be going in. Then the piston goes up, a spark plug ignites the fuel, the piston is shot back down. Then, the piston rises back up to push all the remaining gas out.

Timing chain systems configurations

There are different types of timing chain systems that show unique characteristics, being the main difference in the placement of the camshaft.

The following are some of the most commonly used nowadays:

SOHC roller timing chain

While the traditional OHV (Over Head Valve) timing design, successfully used for many years, had a pushrod engine with the camshaft placed in the cylinder block, this type of engine was rather complex and would easily deteriorate at high speeds or pressure levels.

The OHV design is more suitable for larger engines; so you won’t find it in a modern compact application.

The SOHC (Single Over Head Cam) was then designed to place only one upper camshaft in the engine’s cylinder head. It means that the camshaft is usually placed in the middle of the head which denies the spark plug its ideal location where the valves are operated almost directly by the camshaft; making it easier to work at higher rpms.

The SOHC design offers several advantages over the cam-in-block design. The main one is that the number of moving parts is reduced.

DOHC roller timing chain

A DOHC (Double Over Head Cam) design involves a similarly simple configuration of an engine, with two separate cam shafts riding atop the head. This kind of engine hosts two upper camshafts that split into primary and secondary drive.

This allows the intake valves to be at a larger angle from the exhaust valves, which results in a more direct air flow through the engine and a better fuel-efficiency ratio. In most cases with a DOHC (or twin cam) engine each cam would directly operate its associated valves.

DOHC engines make possible the best of VVT benefits. This configuration shares the same advantages of the SOHC designs.

Distribution for V or W engines

Some high-end and more modern vehicles with a V or a W engine count with a complex and sophisticated design that can use up to four camshafts, involving two-cylinder heads and two rows of cylinders with their respective intake and exhaust valves.

Related content: Car Timing Chain System – Frequently Asked Questions (FAQ)

Different timing chain types

Timing chain is considered a key element of the engine, but not all chains are the same. It exists a wide variety of types that differ in shape and design depending on different requirements as the load.

Roller and silent timing chains are the two most commonly used in vehicles. Being the first one a more complex system which link pins are reinforced by a roller support (or bushing) that accommodates freely rotating steel rollers. The major purpose of this chain type is to reduce friction.

Silent chains, also called ‘inverted tooth’ chains, are designed using metal links, which are held in place by cylindrical pins, which also allow the chain to flex.

Maintenance of Timing Chain Systems

Proper maintenance of the timing chain system is crucial for the reliable and efficient operation of your engine. Here is a summary of the maintenance process for timing chain systems:

1. Regular Inspection:

Regularly inspect the timing chain system for any signs of wear, damage, or abnormal noise. Look for loose or damaged components, excessive slack in the chain, or misalignment. Visual inspections and listening for unusual sounds during engine operation can help identify potential issues.

2. Lubrication:

Ensure proper lubrication of the timing chain system. Follow the manufacturer’s recommendations for the type and interval of lubricant to use. Adequate lubrication reduces friction, wear, and noise, prolonging the life of the chain and related components.

3. Tensioner Adjustment:

Check the tension of the timing chain regularly. If the chain shows signs of excessive slack or tensioner-related problems, adjustment or replacement may be necessary. Proper tensioning is crucial to maintain the correct timing and prevent chain skipping or failure.

4. Replace Damaged Components:

If any components of the timing chain system, such as guides or sprockets, are damaged or worn beyond acceptable limits, they should be replaced promptly. Damaged components can lead to chain instability, decreased performance, and potential engine damage.

5. Follow Manufacturer’s Recommendations:

Always refer to the manufacturer’s recommended maintenance schedule for your specific vehicle. They provide guidelines on inspection intervals, replacement timelines, and any specific requirements for your timing chain system. Adhering to these recommendations helps ensure optimal performance and longevity.

6. Professional Servicing:

For complex maintenance tasks or if you lack experience working with timing chain systems, it is advisable to seek professional servicing. Qualified technicians have the expertise and specialized tools to perform thorough inspections, adjustments, and replacements accurately.

Remember, proper maintenance is key to preserving the reliability and functionality of your timing chain system. By following these guidelines and addressing any issues promptly, you can prolong the life of your timing chain and avoid costly repairs.

Please note that the maintenance process may vary depending on the specific vehicle and engine configuration. Always consult your vehicle’s manual and seek professional advice for accurate maintenance recommendations tailored to your vehicle.

Related content: Timing chain replacement: when it’s necessary?

Industrias Dolz, your expert in vehicle chain distribution

Dolz offers a complete range of complete timing chain kits, tested to perform and with all the components required for a professional and finest repair: premium chain, tensioner, camshaft and crankshaft sprockets, gasket, variable valve timing (VVT), oil seal, guides, screws…

The quality of the timing components will hugely influence your engine’s performance.

So, don’t forget, you should never ignore engine timing problems, since if the timing is off, serious engine problems can be the result.