Changing the water pump or the timing belt are two of the most common operations in any auto repair centre. Although, traditionally these pieces were changed separately when the component itself failed, nowadays, vehicles and components manufacturers recommend changing them at the same time. Not surprisingly, because it offers three important benefits to the client: it saves on labour, it reduces the number of visits to the auto repair centre and it improves both the quality and safety of the intervention, according to Industrias Dolz, the Spanish manufacturer of water pumps for passenger cars and industrial vehicles.

With the increase in the car population lifespan, these interventions have now become part of the regular maintenance of vehicles. Over the life-time of a vehicle, drivers must go to the auto repair centre on more than one occasion to replace these elements before they fail and cause an even greater breakdown in the engine.

Each car manufacturer states the replacement intervals of the timing belt in the maintenance book of each of its models, at which time the auto repair centre should also recommend its customers to replace the water pump, since in the long run it is beneficial both for the car’s motor and to the client’s pocket.

Client benefits

With an average age of the vehicle fleet of 12 years, cars can often function well up to 240,000 kilometres before being replaced. Along that mileage, drivers, on average, will need to replace the water pump twice, and the timing belt another two times, depending on the model.

Thus, if the driver has these two components changed separately within these 240,000 km they will have to visit the auto auto repair centre up to four times, with invoices that will add up to 14 hours plus the cost of the water pumps and timing belts (as well as their additional components: rollers, tensioners … -).

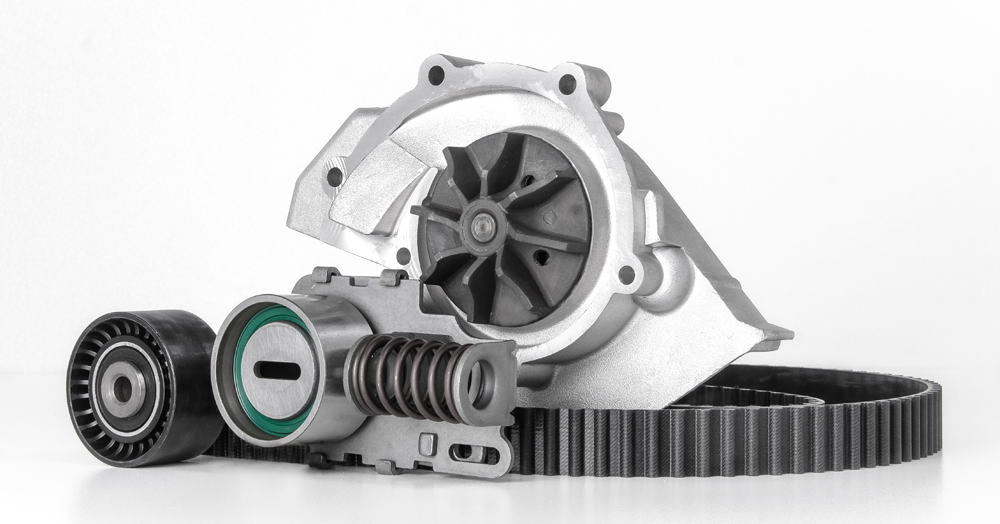

If, on the other side, within the same 240,000 km, those same operations were carried out using distribution kits with pump, clients would reduce their visits to the auto auto repair centre to only two, and would therefore only be charged an average of around 4.30 hours of labour (around 9 hours in total) plus the cost of the complete kit, which is usually cheaper than buying each piece separately.

How do repair centres also gain from it?

To repair it in a single intervention favours the optimal coupling of the replaced components, preventing premature aging and possible damage to the pump bearing, as well as possible failures due to the disassembly and assembly of the unsubstituted part.

It also improves both the quality and the safety of the operation, because when exchanged together, the parts interlock better from the start and the pump bearings do not weaken so easily, minimizing risks. In this regard, before carrying out the assembly of a water pump or a new distribution kit, Industrias Dolz recommends repair professionals to ensure that they have all the necessary tools to avoid damaging the components.

Similarly, Dolz recommends following the specifications of the vehicle manufacturer at all times in terms of tightening torques and tension of the belt. It is not a coincidence that sometimes “the replacement of the timing belt can cause a breakdown in the water pump.

If it is too tight, it will cause the axis of the pump to turn too far, which will slowly give way and cause liquid to leak, or even produce scratches on the blades of the propeller” – says Javier Vicent, Marketing Manager of Industrias Dolz. Industrias Dolz offers auto auto repair centres two video tutorials (in Spanish) where it explains how to assemble water pumps and distribution kit step by step, in a practical and simple way.

Tips to install a water pump:

How to install a distribution kit:

With over 80 references, the DOLZ range of water pump distribution kits covers more than 90% of vehicle sales in Spain and 85% of the European market. Each DOLZ distribution kit, which offers the same quality as the original, contains everything necessary for its assembly: pump with gasket, when necessary, timing belt, bearings and screws.