The concept of ‘thermal management’ refers to the energetic optimization of the thermal balance in a vehicle. With the development of intelligent thermal management solutions, vehicles can successfully host a highly efficient air conditioning system that directs heated and cooled air wherever it is needed in their interior.

Thermal management also applies to the flow of coolant and other fluids in water pumps, providing numerous benefits for the functioning of modern combustion engines and vehicles. This post addresses how thermal management modules in water pumps performance and why they are so beneficial.

What is a thermal management module? Understanding the basics of thermal management

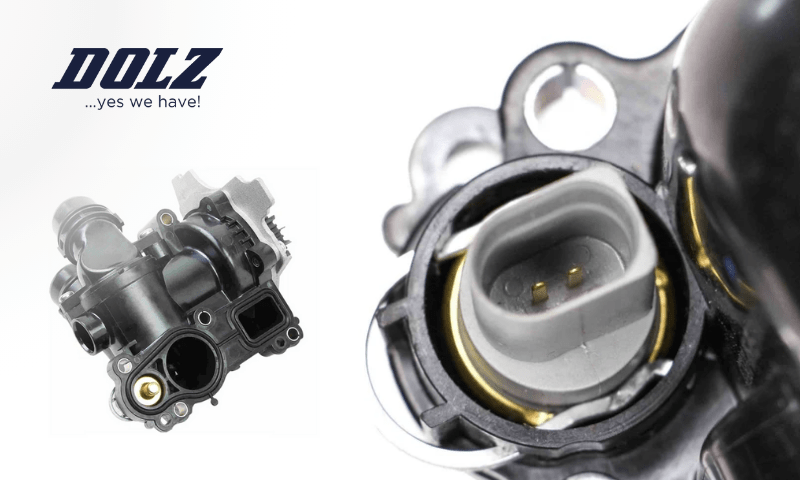

Applied to engine cooling, a thermal management module is an electronically controlled thermostat with electromechanically driven rotary slide valves that regulate the flow of coolant around a vehicle’s internal combustion engine. Unlike conventional thermostats, this module can control the temperature of multiple systems independently and in response to variables.

While one valve closes off the pressurised flow of coolant from the water pump, the other is used to distribute this coolant around. The result is a precise and quickly-adjusting, dynamic model that specifically suits the load and the conditions to the particular requirements at each moment.

TMM crucially improves water pump’s energy efficiency, by meticulously controlling that the temperature stays consistent while the engine is operating. The fact that it operates on a proactive basis makes it able to reduce the time needed to hit the optimum engine temperature by as much as 50%.

TMM’s features therefore enhance the water pump’s innate activity; satisfying the engine’s basic cooling requirements, minimizing combustion chamber fluctuations due to speed changes, and permitting the quick heating of cold blocks by cutting warm-up times by half.

How do thermal management modules work?

How exactly do thermal management modules achieve such a chameleonic adjustment to circumstances? The secret relies on one word: information. Data is measured through a position sensor and transmitted to the TMM, which changes its resistance and regulates the injection to adapt the combustion to the temperature of the engine.

Water pumps with thermal management modules use various cutting-edge technologies and features that include electronically-controlled ball valve modules, temperature sensors and a system of connected components with the capacity to retain thermal mass in the cooling system.

TMM’s main components include the water pump itself, the two rotary slide valves, the cooler feed, the worm gearbox, the oil cooler return, the electric motor and the outlet from the engine.

The number of connections to the different engine-related areas allows TMMs to safe-control the temperature of components such as the cylinder head, the cylinder block, the engine oil, the transmission oil and the interior heating amongst others.

The integration of several switching functions into one single module and its compact design with high integration capabilities enable a low integration outlay and a range of opportunities for the vehicle’s quality, life cycle and user features.

Keep reading: Dolz water pump: Maintenance tips and best practices

Benefits and opportunities of using a thermal management module

With the thermal management module, the car part aftermarket has brought about a whole new evolutionary stage. This module enables the optimal operating temperature for internal combustion engines to be reached and adjusted within extremely short periods of time, offering the following 4 benefits and opportunities:

1. High-efficiency engine cooling

TMM is an innovative solution that delivers high-efficiency air conditioning and optimal engine cooling. Considering the vehicle’s operating state and driving situation, it controls the volume flow of coolant in a range of circuits, thereby increasing the system’s productivity.

The thermal management module uses the optimum control of the individual coolant flows for fast and safe heating and the subsequent cooling of the engine (split cooling).

2. Reduction in fuel consumption and CO2 emissions

By controlling the temperature of all combustion engine components based on their operating point, the result is a more eco-efficient vehicle that takes a step further towards CO2 saving. It is therefore key for reducing fuel consumption and CO2 emissions by up to 4%.

3. High resistance to wear and thermal shocks

TMM’s hermetic seal integrity and excellent drainage significantly reduces pressure loss, and its individual components can be operated at higher temperatures than what would be possible with a system controlled by a thermostat.

Furthermore, the power battery can work efficiently within the optimum operating temperature range for a long period of time, ensuring battery safety and reducing the effects of wear and corrosion.

4. Single unit reduces development cost and complexity

Previous functions have been standardized and integrated into one single module, reducing assembly times, development costs and complexity for manufacturers. TMM’s compact design allows for high integration capabilities and a resulting better cabin comfort.

The independent housing can even be used in hybrid and electric battery cooling, controlling the temperature of generators, hybrid modules and batteries. This is an opportunity for manufacturers to extend their range of vehicles.

Installation of water pumps with thermal management module

The installation process of water pumps with thermal management module is similar to that of traditional water pumps. However, there are a few additional steps that need to be taken into consideration. Firstly, it is important to ensure that the cooling system is clean and free from any debris or contaminants that could potentially clog the system. Secondly, the thermal management module must be properly aligned with the water pump and securely fastened in place. Finally, all connections and hoses should be checked for any leaks or damages. It is also recommended to refer to the manufacturer’s installation instructions to ensure that the installation is done correctly.

Dolz, water pumps of the latest technology

Dolz’s water pump A281 has an integrated thermal management module supported by an auxiliary belt that enables the optimal operating temperature of a vehicle in a short period of time and with high precision.

Professional water pumps manufactured with an optimized design to ensure cooling at high RPM’s. Visit us to discover the range of water pumps available!