Beyond knowing that the water pump is the heart of a vehicle’s cooling system, it is essential to know that it is made up of different parts that, although some go unnoticed, are extremely important and essential for its proper functioning. It depends on all these parts that the cooling system can maintain the thermal balance of the engine in perfect harmony, as we have already seen in previous articles. In today’s post we will know the shafts and bearings of Dolz’s water pump sand its main characteristics.

Why water pump bearings are more important than you think

The bearing allows to reduce friction between moving parts. It may prevent a motion by controlling the vector and normal forces that bear on the moving parts.

That is, it supports and guides components that rotate with each other. It serves as a support, facilitating sliding while reducing the friction generated by transmitting movement of the motor rotation to the cooling circuit through the joint rotation of the shaft with the pump impeller.

Types of water pump shafts and bearings

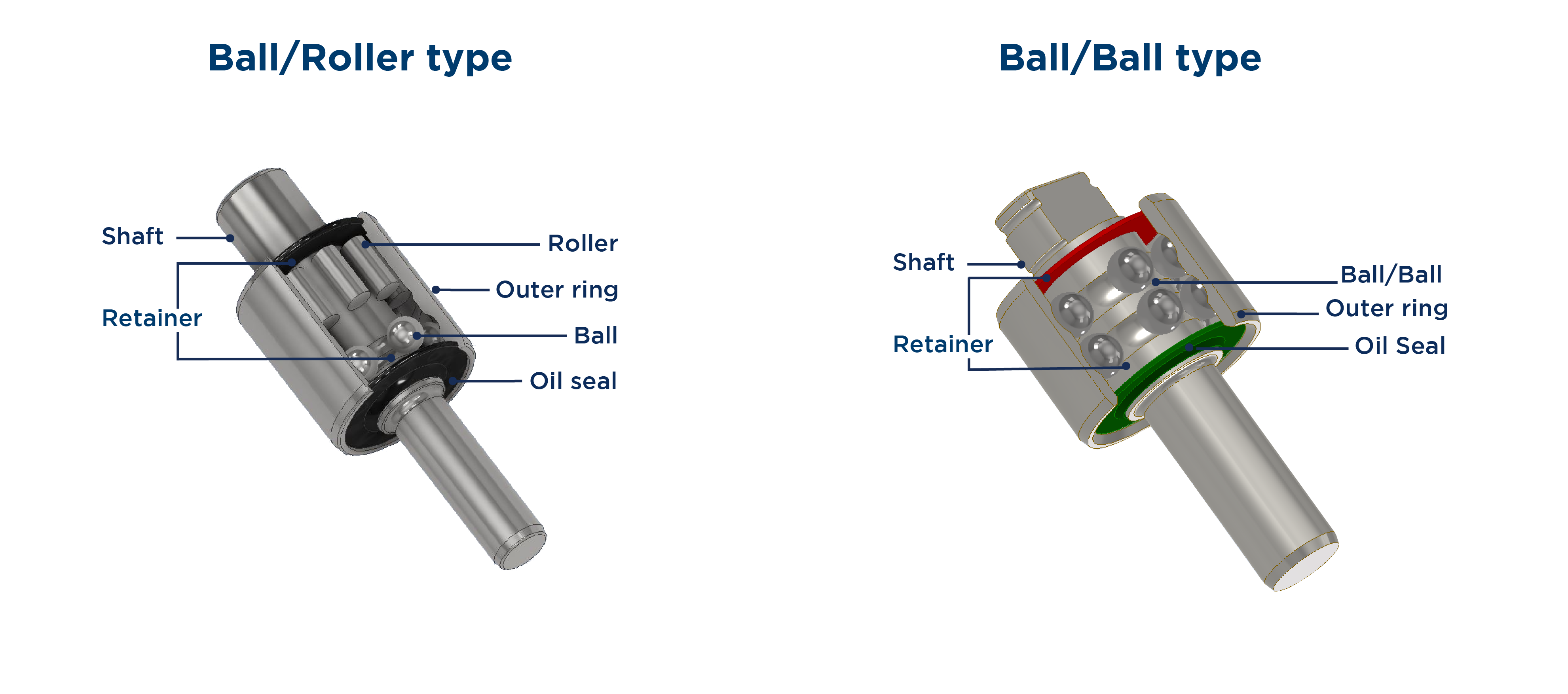

Normally the water pumps are equipped with an integrated shaft. We can find different types of bearings depending on the type of load they must withstand (axial, radial, etc.) or the type of construction (ball type, roller type, etc.). There are two basic types of DOLZ water pump shafts and bearings:

- Roller-Ball: used when it is required to support a high load index for a limited construction space.

- Ball-Ball: used when high speeds are required and a lower load index is required.

Most bearings are made up of rings with races (inner and outer ring), rolling elements (balls / rollers) and a part called a cage. The cage is in charge of separating the rolling elements at equal distances, ensuring their position between the inner and outer race, which allows them to roll without any problem. The rings and rolling elements are made of steel and the cage in a thermoplastic material (type PA6.6)

Keep reading: How do water pumps with a thermal management module work?

Choosing a water pump bearing: Dolz’s expertise

To obtain the best conservation and the highest performance of the water pump, it is advisable that it has high quality components. In the same way that the different automotive parts evolve over time and with new technologies, axles and bearings have also been the subject of continuous innovation.

Among the possible bearing failures we find problems due to abrasions, wear, rust or jamming. Sometimes a consequence of improper installation. Therefore, in order to guarantee the longest possible durability of our water pump, it will be essential to correctly fit it and ensure that the bearing supports the loads required for each specific application.

DOLZ Tip: Every precaution is good, therefore we recommend stopping the engine if excessive noise is detected (bearing damage), do not systematically fill the expansion tank with coolant if you notice that the water pump is leaking and go as soon as possible possible to your trusted workshop to locate and verify the damage caused.

Dolz provides shafts and bearings that meet the durability requirements defined by each vehicle manufacturer, suitable for each engine application, providing high reliability thanks to the quality of its materials and effective lubrication of the part.