Increasingly, heavy vehicles set as one of their main objectives to improve fuel consumption standards and engine efficiency, proof of this is the growing trend of cooling demand.

Heavy vehicles such as trucks or industrial vehicles involve large engines and therefore generate a large amount of heat. That is why the cooling system is considered a key element for good engine performance. Overheating can increase the risk of engine damage, so it is essential to ensure that the engine does not experience additional stress due to extremely high temperatures.

Keep reading to learn more about electromagnetic truck water pumps, their variable operation and how they differ from traditional mechanical water pumps.

What is an electromagnetic water pump?

There are different ways to regulate the coolant, some of them are carried out by an electro hydraulic actuator, or a belt drive, also by electrical activation on the water pump back housing (thermostat) or also by an electromagnetic coupling.

In relation to the last one mentioned, the use of this electromagnetic technology has spread to form part of systems such as vehicle air conditioning or engine cooling system, meeting the growing demands for efficiency and flexibility in engine performance.

The main difference between a mechanical water pump and one that has the EM (electromagnetic) clutch is that this electromagnetic clutch system can automatically adjust output flow of the water pump more meets the demand of motor. On the other hand, the traditional water pump will circulate the coolant in a fixed and constant way because its speed is directly connected to the speed of the engine.

How does the electromagnetic clutch work?

In an electromagnetic clutch, the pulley (rotor) is independent of impeller. The connection between both elements is achieved by pressing two friction elements using an electromagnet.

When this electromagnet is activated, the clutch engages, and both the rotor and the impeller rotate together. Without current, a spring separates the friction elements leaving the rotor free of the system. Clutch system control is performed by the engine control unit (ECU) using thermal sensors located on the engine.

To guarantee a minimum flow of the pump when the electromagnetic clutch is deactivated, a second magnetic clutch is fixed to the rotor. This second clutch does not guarantee joint rotation between both components, but it guarantees a 50% and 60% of the flow between them when there is a friction coupling.

In most situations, this flow is enough to keep the engine properly cooled and to have this type of clutch, which has no friction or contact between the rotor and the impeller, significantly reducing power consumption and besides fuel consumption. Only in some situations as per example high outside temperatures, a 100% flow is necessary and, in those cases, the electromagnet will activate to generate a total coupling by friction.

For all the above considerations, its main advantages are:

-

- Reduces fuel consumption.

- Provides greater flexibility thermal management.

- Reduces system inertia and increases tolerance to changes in revolutions.

- Guarantees minimum flow for normal circuit operation if an electrical system failure occurs.

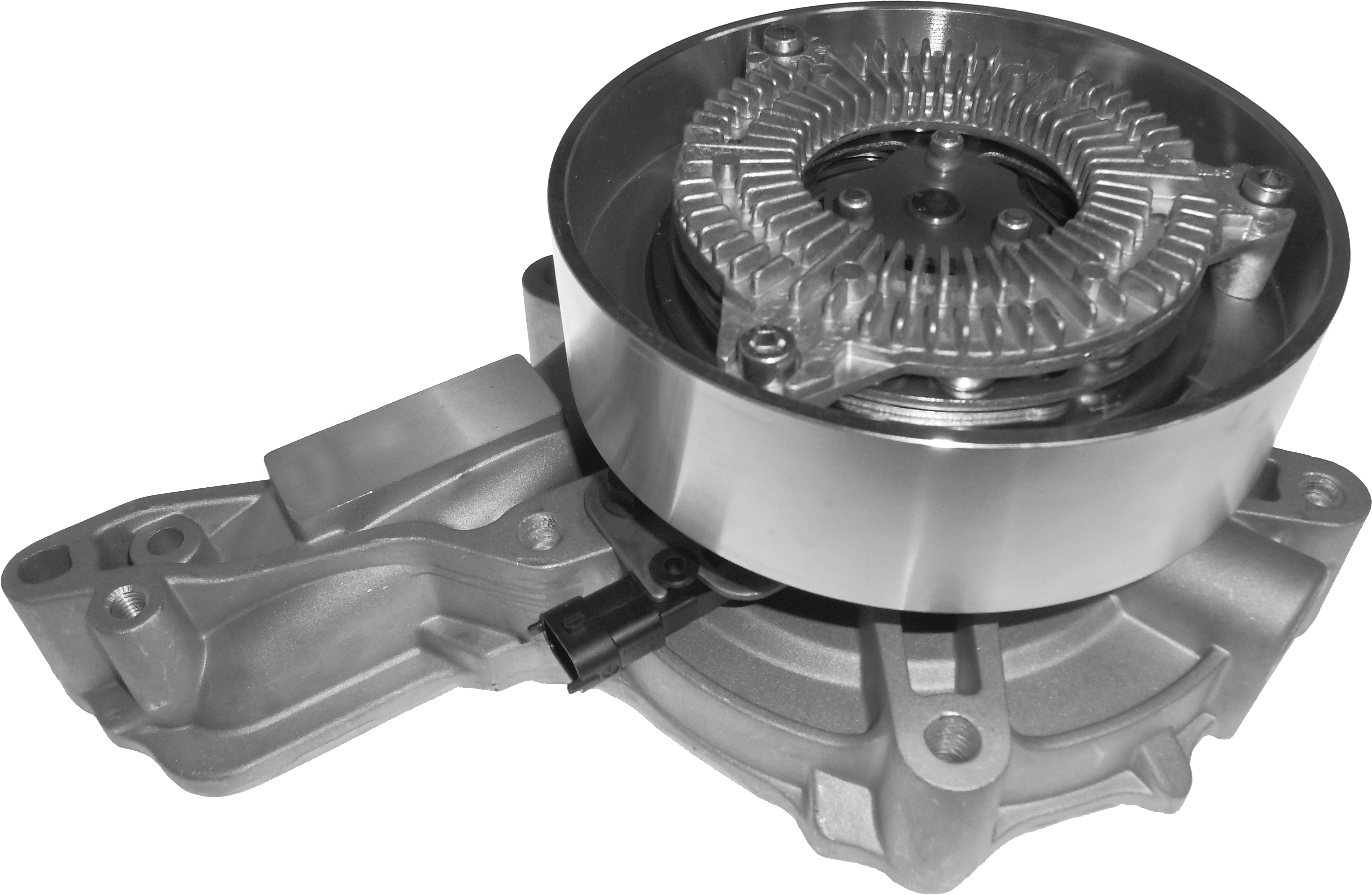

*V501 Dolz electromagnetic water pump for truck

Related content: Truck water pump: How to select the correct one?

Main components of the EM clutch

- The rotor, the pulley, the element that is in contact with the belt fixed to the water pump.

- The static friction ring, attached to the rotor, and the spring-loaded secondary friction ring, engaged to the impeller through the inner shaft.

- The electromagnet, attached to the water pump, which acts on the spring-loaded friction ring and engages it on the static ring. And then, there is a secondary magnetic clutch magnets.

- The secondary clutch armature ring, over the magnets.

- Heat dissipation system

Dolz Electromagnetic Water Pump

Industrias Dolz has been manufacturing and distributing high-quality water pumps for passenger cars, commercial & industrial vehicles since 1934.

Among the strengths of Dolz water pumps are:

- Full in-house production …All in Dolz

- Self-lubricating silicon carbide (SiC) seals, with HNBR rubbers and synthetic graphite contact rings to increase durability and guarantee performance.

- OE equivalent.

- ISO 9001:2015 Quality Management System

- All water pumps are supplied with the necessary fittings/gaskets.

Dolz has a manufacturing plant built on an aera of 25,000 square meters focused on innovation and market demands, automation and robotization in production processes and logistics efficiency. It manufactures more than 100,000 automotive water pumps per week and has a permanent stock of more than half a million water pumps.

Keep reading: …All in Dolz. In-house production end to end.

Contact to discover more about our full range of electromagnetic water pumps and other Dolz product lines.