Water pumps have a long service interval, but this often means that car owners underestimate the eventual need for a new water pump. Although water pumps wear over time, certain factors as bearing damages could be responsible for speeding up this process.

Function of the bearings in the water pumps

The water pump bearing has the function of holding the loads transmitted by the timing and the accessories belt or the gears and to connect the engine movement with the water pump impeller turning.

Normally, all the water pumps are equipped with integrated shaft. In this picture we can see a typical water pump bearing, composed by the outer ring, the bearing shaft, a row of rollers and a row of balls, all of them manufactured in stainless steel.

Types of bearings used in the automotive water pumps

We can find different types of bearings depending on the type of load they must withstand (axial, radial, etc.) or the type of construction (ball type, roller type, etc.). There are two basic types of automotive water pumps shafts and bearings:

- Roller-ball bearing, used when it is required to hold high radial loads.

- Ball-ball bearing, used when there are required high speeds, radial load not very high and even a low component of axial load.

Industrias Dolz select the bearing more appropriate to each engine application to cover the high levels of quality and durability for the best performance and efficiency.

Typical bearing damages that are produced in water pumps

1.Excessive timing belt tension

There are vehicles that require a manual tensioning of the timing or the auxiliary drive belt.

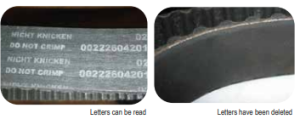

The timing belt flat side letters use to have marked the belt trademark and belt technical characteristics. If the tensioning of the belt is very high, these letters disappear totally due to the excessive contact with the rollers or the blocking of one roller.

Also appears red coloring in roller and balls. This means that they are worn. Roller and balls race ways are also worn.

Bearing damages produce excessive noise. It is an indicator to stop immediately the engine to avoid engine breakdown.

2.Tensor roller incorrectly tightened vibrations

If the screw that fix the tensor roller to the engine become loose (it was not tightened at correct torque), then it will be produced belt vibrations and whips. Consequence of that, it will be produced an irregular wear of the belt flat side letters very similar to that appears in the bellow picture.

Bearing shaft race ways wear due to irregular loads applied to the water pump bearing.

3.Entry of coolant to bearing

If the water pump leaks between two dynamic seal contact faces, it will be produced an infiltration of coolant inside the bearing that will be removing the bearing internal protective grease. Without this grease, the bearing life will be reduced considerably because there will be produced a contact metal-metal of the bearing elements.

Here an example: Coolant has infiltrated inside the bearing removing it internal protective grease.

If you detect coolant loses by the water pump exhaust hole, you must stop the engine and go to the mechanic.

4.Irregular function of other engine components

The water pump is connected to other engine parts by the timing belt, the auxiliary drive belt or gears. If any of these elements don’t work properly, it should generate whips and vibrations that will be transmitted to the bearing, reducing considerably its service life.

Maybe you are interested: …All in Dolz. In-house production end to end

Dolz water pump shafts & bearings: your safety choice

The water pumps manufactured by Industrias Dolz include bearings that have same quality and service life than original equipment.

For long bearing life should be followed these requirements:

– Tensioning the timing or accessories belt according OE specifications.

– To check that the screw that fix the tensor rollers to the engine is tightened to the correct torque.

– Repair the engine parts that are damaged (specially if they are connected to the water pump by the timing or the aux drive belt).

And also it is needed to have the following precautions:

– Stop the engine if excessive noise is detected (bearing damage).

– Do not refill the expansion vessel with coolant in a systematic way if it is observed that the pump leaks, go to the workshop to verify the damage.

Dolz’s water pumps have their water tightness rigorously checked in a calibrated and extremely precise automatic leak detection machine. This allows us to hold a guaranteed rate that is less than a 0.05% in all our aftermarket car parts.

For further information on any of our product lines, receive commercial information or technical product specifications (including assembly notes), CLICK HERE.