An engine can be classified based on its configuration. We can find different types of belts, such as the main timing belt, the belt that drives the oil pump or the accessories belt.

Accessory belts or auxiliary drive belts have become increasingly relevant with the evolution of vehicles and their current possibilities. In fact, as FEAD (Front End Auxiliary Drive) systems have become less spacious in physical terms, their importance in terms of propulsion has also increased significantly, requiring more power capacity with fewer cylinders and space.

In such a context, the role of auxiliary belts has come to the fore, evolving considerably over the years in both design and materials. Some changes that were reflected in increasingly longer accessory belts and more durable materials.

In today’s article, we learn about the main types of transmission belts that are housed in the vehicle, and we talk about the particularities of each of them.

What is the main difference between an auxiliary drive belt and a timing belt?

Driving belts are power transmission devices that are able to transfer power between elements such as shafts, pulleys or sheaves. Although they may have a similar appearance, both play two completely different roles.

The timing belt is used to synchronize the rotation of the crankshaft and camshaft so that the engine valves open and close at the precise time for the intake and exhaust of each cylinder.

On the other hand, the accessory belt or aux drive belt is the one that transmits the movement of the crankshaft pulley to different components of the vehicle, such as the alternator to charge the battery and to power the electrical system when its engine is running or the power steering. It’s attached to the crankshaft and camshaft via several pulley, while the tensioner pulleys rest on the outside.

While the timing belt almost always has one side full of notches or teeth (they are called toothed or synchronized for that reason), the auxiliary drive belt usually does not have notches but parallel longitudinal grooves and is usually somewhat narrower and thinner than the first one.

Types of transmission belts and their application

Transmission belts are generally made of rubber and can be classified into different types depending on their application.

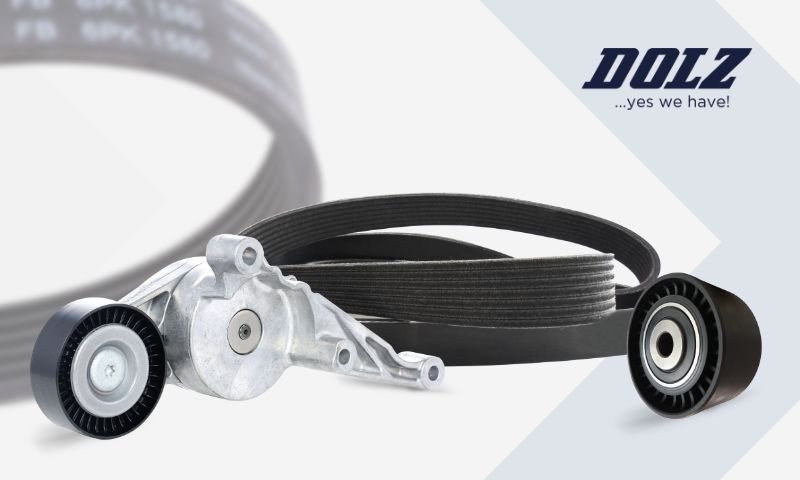

The auxiliary drive system transmits power from a drive pulley to accessories. There is the classic design with multiple belts that drive different accessories like the alternator and power steering pump. Although it is also common to find systems with a serpentine belt capable of driving all the accessories by itself. It is true that in some engines you can find toothed or synchronized belts such as timing belts driving an accessory, generally the two most common types of auxiliary drive belts are the following:

V-belt

The V-belt, shaped like an isosceles trapezoid in cross section, is responsible for driving so-called secondary or auxiliary accessories. Years ago, this system activated elements such as the electric generator and the water pump, but now others have been added, such as the power steering pump or the Air Conditioning compressor.

These types of belts solved alignment and twisting problems by focusing on the pulley groove. And more importantly, they had a much stronger grip than the auxiliary belts of yesteryear because their shape is basically a wedge.

These belts are characterized by being thinner and smaller and generally only drive one peripheral at a time. So, it’s quite common to find multiple V-belts on an engine, but only one serpentine belt.

Currently, most of the modern applications of this type of auxiliary belt have been replaced by the ribbed or poly-V belt that we will see below.

Poly V-belt

The poly-V belt (also known as auxiliary ribbed belt, poly belt and poly vee belt) is a type of belt that has played a crucial role in the capabilities of vehicles to transfer greater power and overcome the challenges presented by today’s increasingly complex systems.

This type of belt is a further development of the V-belt and has several longitudinal grooves in its design.

As tension increases, this type of belt fits hard into the grooves, increasing friction and thus transmitting torques with minimal power loss.

Due to its flexibility and high efficiency, the Poly V belt has become one of the most popular choices among vehicle manufacturers.

For this reason, its multiple advantages take on more prominence than ever:

- Support higher loads.

- It’s more flexible.

- Allows enveloping angles in small spaces.

- Increased system performance.

- Support higher speeds.

Unlike other drive belts, it has its teeth or grooves parallel to the direction of the belt.

Choosing the right auxiliary drive kit will ensure the vehicle runs smoothly and efficiently over a longer life cycle.

When should an auxiliary drive belt be replaced?

An auxiliary drive belt has a very variable useful life depending on the use of the vehicle.

Made of highly durable synthetic rubber (Ethylene Propylene Diene type M or EPDM), it is a component that must be inspected visually to detect the need for its replacement.

If the belt is worn, it will have cracks, fraying or irregularities of all kinds.

Although among the most obvious symptoms of failure of the auxiliary belt system are:

- Steering hardening.

- Vehicle battery failure.

- Failure in the air conditioning.

- Humming in the engine.

Related content: Understanding the Drive Belt Tensioner (Friction Wheel)

Dolz Kits, knowledge and experience at your service.

The Dolz Kits Range includes:

- Timing Belt Kits with water pump.

- Timing Belt Kits without water pump.

- Auxiliary Drive Kits.

- Timing Chain Kits.

All of them are manufactured according to original equipment (OE) specifications and are guaranteed for 2 years from the date of purchase or 50,000 km.