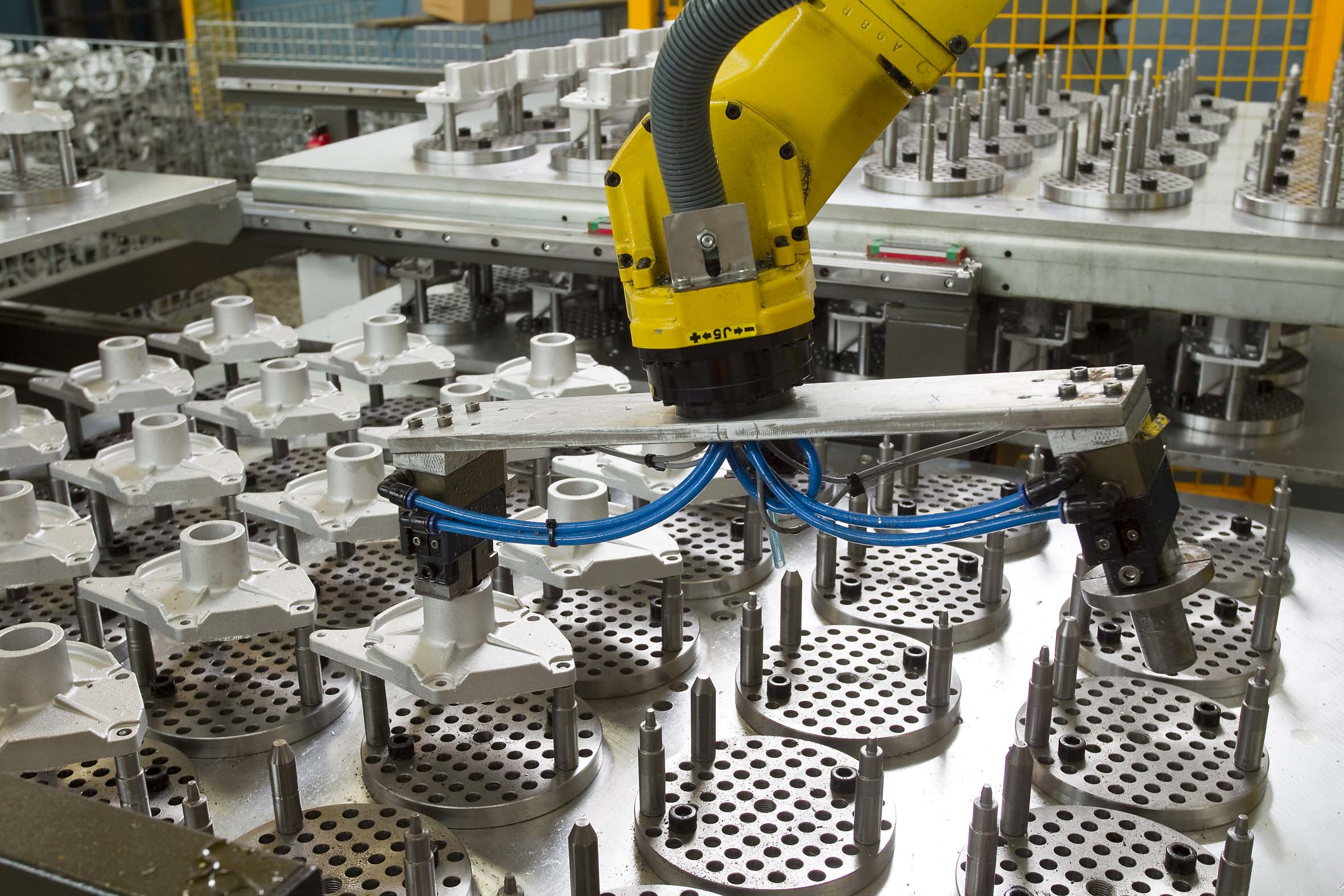

Industrial robotics, through robots and CNC machines, is allowing the development of automated solutions to improve and increase productivity. At Industrias Dolz we continuously pursue optimization of our manufacturing processes. For this reason, our production plants have robotic automation process, providing our customers with high-tech solutions.

In today’s article we talk about our automated processes, dedicated exclusively to the manufacture of water pumps for passenger cars and industrial vehicles.

How is robotics used in manufacturing?

Industrial robots began to be used in industry in the early 1960s. Since then, they have come a long way.

The application of technology to production processes is mainly used with the intention of performing repetitive tasks automatically, accurately and with minimal human intervention, especially if that task is complex or involves some risk.

Some of the advantages that we find in automated manufacturing are:

- Optimizing repetitive routine processes.

- Increases go-to-market speed by maximizing productivity.

- Flexible and customer-oriented production, adapted to current demand.

- Increases agility in operation.

- Increases security in the processes.

At Industrias Dolz we have different CNC turning center machines and lathes fully automated integrated within our machining and assembly sections, they involve the use of computers to control machine tools. Automating these processes gives us the possibility to improve our productivity and offer a better service to our customers, optimizing our manufacturing processes, taking our water pumps to the next level.

At Industrias Dolz we have different CNC turning center machines and lathes fully automated integrated within our machining and assembly sections, they involve the use of computers to control machine tools. Automating these processes gives us the possibility to improve our productivity and offer a better service to our customers, optimizing our manufacturing processes, taking our water pumps to the next level.

Machining Process

Adapted by industry 4.0, Dolz’s machining area has 30 lathes and CNC machines. The difference between them is that in the CNC the workpiece does not rotate, the elements of the machine rotate on the part to machine it. On the other hand, the lathes are fixed, and it is the workpiece that turns on itself.

Thanks to the “Dual Pallet” high-speed system, the operator loads the machine while others are machining, achieving uninterrupted machining and providing 24-hour production.

Besides to maintaining original equipment specifications, it offers the possibility of making different part numbers (references), so that the production of our plant is flexible.

Assembly Process

The automotive water pump consists of 5 elements: a body, the seal, the shaft, the pulley, and the impeller. Its assembly is carried out in two different phases:

The automotive water pump consists of 5 elements: a body, the seal, the shaft, the pulley, and the impeller. Its assembly is carried out in two different phases:

- 1st Phase: assembly of the body, the seal and the shaft.

- 2nd Phase: assembly of the pulley and impeller.

After the first assembly phase, the tightness control is carried out with air in 100% of the workpieces (less permissive than water). Once finished and guaranteeing the optimal state of the elements, the second phase of the assembly is completed.

The Dolz assembly area is made up of 14 assembly lines that allow the final assembly of the water pump. Of all of them, 4 are robotized and have 2 presses and 2 for tightness testing and can reach 3,000 pieces per series.

In addition, one hundred percent of the machines have a quality control process, both force and distance control, ensuring the correct tightening, capable of accepting or rejecting the workpiece by itself.

Further information – All in Dolz, In-house production end to end

…All in Dolz

By controlling all the steps in the production process, Industrias Dolz consolidates itself as a true specialist in water pumps for passenger cars and industrial vehicles. Offering a full wide range of more than 1,300 part numbers of water pumps, all of them equivalent to OE (original equipment).

We manufacture more than 5.5 million units per year over a range which comprises:

- Water pumps for passenger cars

- Water pumps for industrial vehicles

- Auxiliary electric water pumps

- Variable water pumps

- Electric water pumps

As manufacturers, robotic automation process allows us to provide an excellent quality by eliminating the subjective factor of human intervention, achieving lower margins of error and more precise processes. Proof of this is the almost zero guarantee rate that our products have, less than 0.05%.

Therefore, the automation and integration of the different processes (injection foundry, machining, assembly…) under the same roof allows us to improve quality, shorten delivery times and reduce costs.

Contact to know more about our robotic automation process, our water pumps and other Dolz product lines. We are happy to help you!