Fundamental things and its importance

An oil seal, also known as crankshaft retainer, is a small device, but essential to ensure the proper engine operation. It plays a key role in all moving parts of an engine, acting as a physical barrier. This mechanical seal fulfils the dual purpose of sealing a rotary shaft to maintain the necessary lubrication (avoiding leaks) and preventing other foreign matter from contaminating shafts and bearings in the rotary shaft equipment.

It is generally used in the union of two lubricated parts, so that it hermetically seals both sides. Therefore, it guarantees the proper engine operation and helps to maintain the vehicle’s distribution system in better condition.

Oil seal characteristics

Several variables must be considered when selecting oil seals. The physical dimensions and materials will vary depending on the environment of use. In addition, oil seals must remain lightweight, compact, and exhibit high self-lubrication performance.

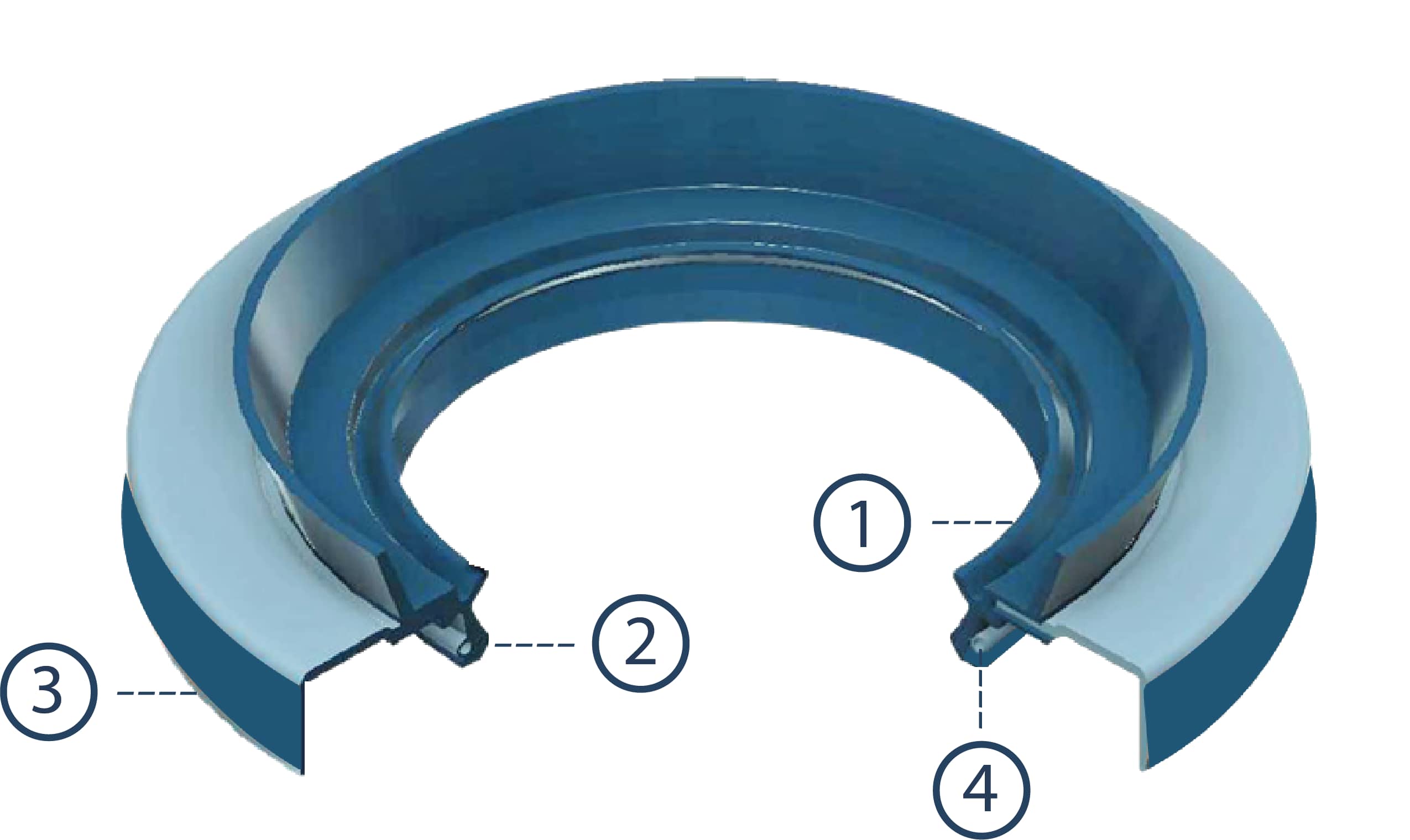

Most oil seals consist of some basic elements that configure their structure, such as the sealing element, the metal case, and the spring:

- Dust lip: prevents particles from reaching the sealing lip.

- Sealing lip: guarantees dynamic and static sealing.

- Metal case: the metal case supports the rotary shaft seal, ensuring the structural stability.

- Spring: spiral shaped, ensures constant pressure and maintains the optimal force to the shaft.

Aspects to consider when selecting oil seals

Operating conditions such as the engine’s temperature, position, size, pressure and shaft speed largely determine which individual oil seal composition is most suitable for every individual application.

Some aspects to consider when selecting this component are:

- Temperature: The temperature within the oil seal environment is the main factor that dictates the composition of an oil seal. Generally, there is a range of set temperatures that are optimal for that material. If the operating environment is too cold, the seal may become brittle and, at high temperatures, the seal material may show increased elasticity and become leaky.

- Pressure: As the pressure increases, the radial load and the friction of the sealing lip increase in contact with the shaft. As with temperature, each oil seal has a recommended pressure for optimum performance. Excessive pressure causes the seals to wear more quickly and consequently have a shorter life.

- Shaft Speed: The speed at which an oil seal can operate effectively depends on the previously outlined conditions together with the design of the seal itself. Some designs allow for a range of maximum peripheral speeds and are therefore more suitable for larger shaft diameters. Speeds below and above the recommended range can cause friction and thus impact the sealing material.

Common causes of oil seal failure

Like any element of the engine, oil seals are subject to wear. Over time they can lead to possible leaks of lubricating liquid.

Among the most common causes of oil seal failure are:

- Installation inaccuracies, such as placing the seal in the wrong position in its housing or handling it incorrectly.

- Improper use of sealants.

- Imperfections on the shaft (burr, corrosion, etc.), which will directly affect the service life of the oil seal.

- Cracks or swelling of the component due to extreme temperatures, causing premature deterioration of the oil seal material.

- Other maintenance factors, such as insufficient lubrication inside the engine.

Oil leak: the most frequent failure of the oil seal

Finding oil spots under a parked vehicle can be both worrying and stressful for any vehicle owner. If the seal’s leak is small, oil may start to accumulate on the underside of the engine. But as the leak gets bigger, the oil leak will become visible in the front side of the engine.

Wear and oil loss remains two of the most frequent signs of engine seal failure and, if not paid attention to, it can give rise to a breakdown in the vehicle’s system. Regular maintenance and routine oil changes minimize the issues associated with oil seals and potential oil loss.

Keep reading: Effective lubrication, key factor of the chain

Dolz, your safety choice

Oil seals included in the Dolz timing chain kits are lightweight, high-precision seals with wear resistance and made from the highest quality materials.

It is recommended to replace all timing elements in a single operation, ensuring an optimal coupling of the components and thus avoiding premature aging and possible future engine failure.

At Dolz we put our almost 90 years of knowledge and experience at your service to provide you with an optimal replacement of your components.

Are you looking for the best solutions for the distribution of your vehicle?

Contact us to learn more about our full range of products!