The automotive and industrial sector is facing an uncertain outlook in production, due to shortages and supply-chain disruptions.

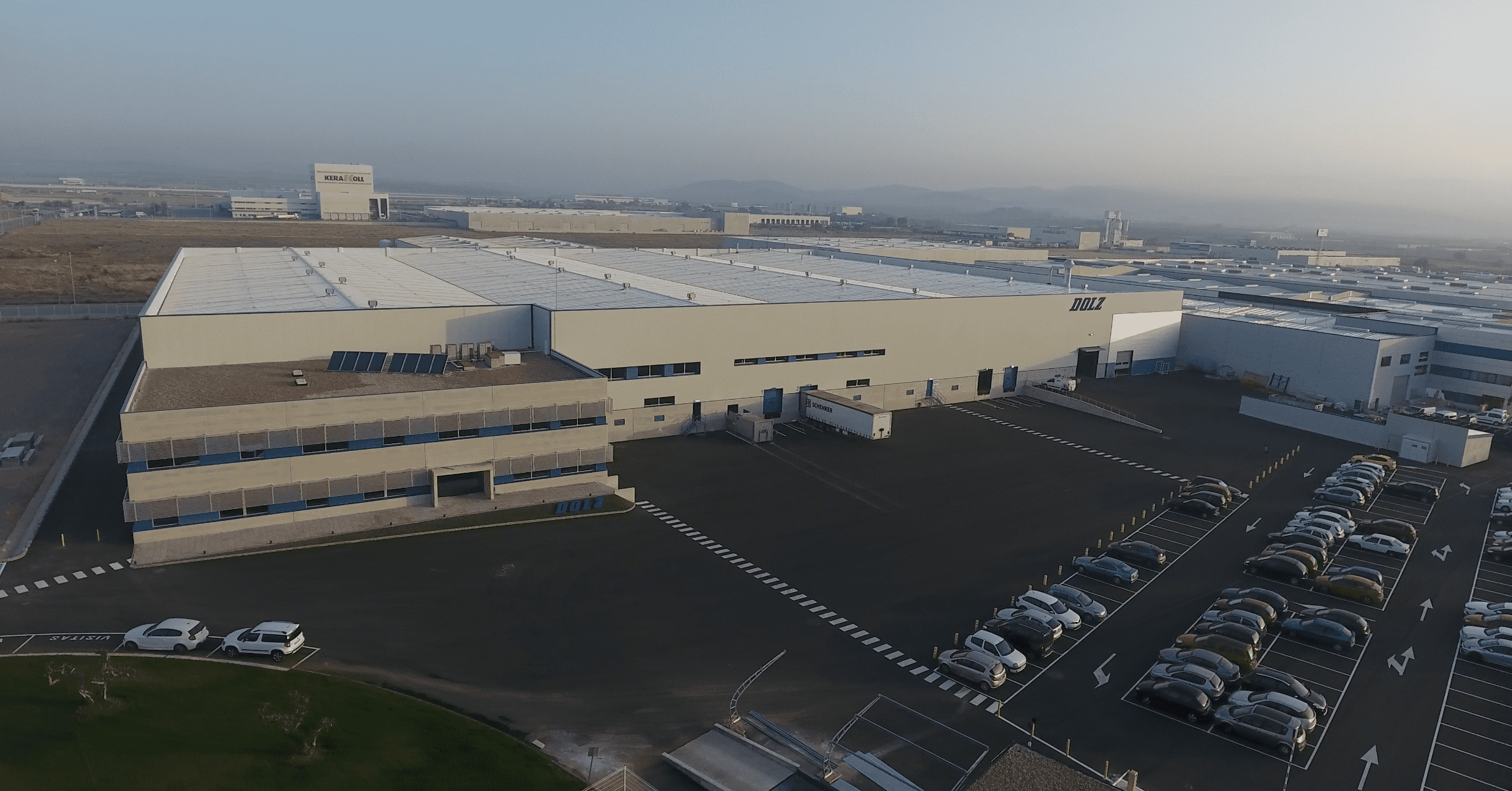

At Industrias Dolz we can guarantee a production continuity, being one of the few companies in the sector having an entire in-house manufacturing process end to end.

…All in DOLZ

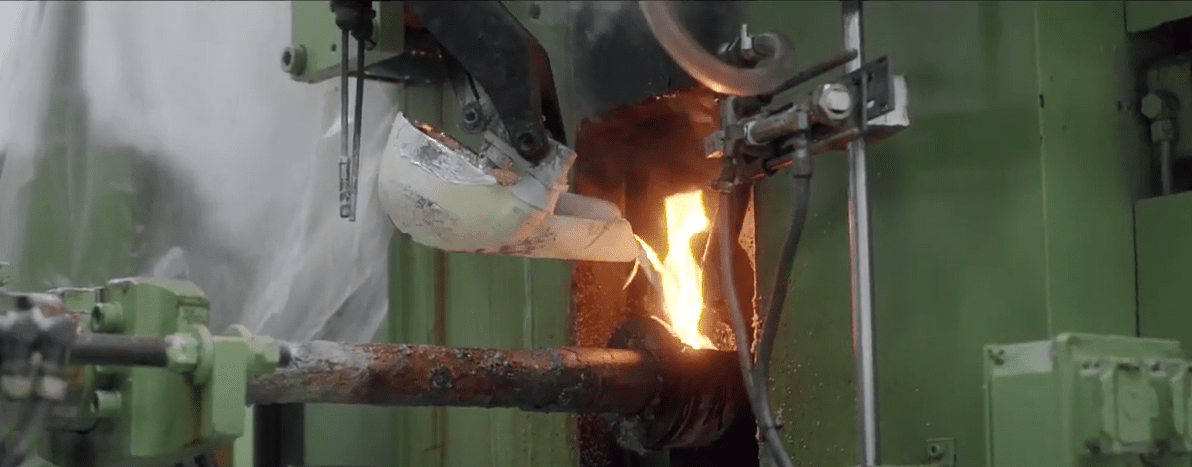

At our European plant based in Spain, we have a melting furnace for die casting, making Industrias Dolz one of the few companies in the sector integrating this process in its own facilities, differentiating us in the market with a clear competitive advantage.

Having a full implemented manufacturing processes ‘under one roof’, at Industrias Dolz can guarantee the total quality of our products, since all processes have quality audit, supplies and reduced lead-times. It has also been possible thanks to the implementation of the Lean Manufacturing method in our facilities.

Foundry 24-hour

The foundry can assure us a manufacturing independence, generally rare in the aftermarket industry.

A 24-hour active casting, that grants all internal manufacturing needs, with an actual output over 17.000 units per day.

In this department the aluminium is melted, and afterword injected into the moulds robotically.

Injection, Machining, Assembly & Stock management

Our plant includes an injection department, machining, assembly, packaging and warehousing area. A fluid process adapted by industry 4.0

- Injection: 100% automated and robotised.

- Machining: Highly efficient robotization process and precision machineries that guarantee OEM standards.

- Assembly: Automated lines to maximize efficiency.

- Stock management: Automated stock management to ensure an efficient service.

Benefits of in-house production

Our experience as manufacturers allows us, thanks to an entire in-house manufacturing process, to offer to our customers the best possible level of service:

- Guaranteed fast delivery times.

- Flexibility and customer orientated manufacturing.

- Easier quality controls of the product.

- Easy and fast reaction in matching market’ evolutions.

- Costs efficiency with benefits towards greater investment/innovation.

Dolz, without limits

Dolz has a manufacturing plant, built on an area of 25,000 square meters oriented to innovation and market demands, automation and robotization in production processes and logistics efficiency. It manufactures more than 100,000 automotive water pumps per week and has a permanent stock of more than a half million pumps.

Besides, at Dolz we have a Lean Manufacturing method. A management model to reconcile effectiveness, efficiency, and innovation in our processes.

The goal is to achieve maximum efficiency but also maximize the customer value creation ensuring the optimization of our resources and achieving continuous improvement of our products.

A commitment to quality and continuous improvement reflected in our certification with ISO 9001 quality standard and by the ISO 14001:2015 environmental certification.