About the different parts that make up the Dolz water pump, in this post we are going to focus on the component in charge of protecting against any possible leak and contamination: the dynamic seal.

Along with the bearing, the seal is the most important element of the water pump, since its tightness depends on them. Therefore, its main function is to protect the bearing by preventing leaks and contamination from the coolant getting a hermetically sealing water pump.

The challenge in this process is to allow the rotating shaft to enter the “wet” area of the pump, without allowing some of the coolant to escape. And for this reason, it is necessary that there is a seal between the pump and the casing, supporting the pressure of the process and the friction caused by the shaft rotation.

Traditionally, this was achieved through stuffing: a cord impregnated with waterproofing grease, that was wrapped around the shaft behind the turbine.

A technique that has evolved as new engines have been developed in the automotive sector. Therefore, it was necessary to create more reliable and durable configurations to obtain the highest possible seal strength properties.

Seals of the latest technology

At Industrias Dolz we have self-lubricated silicon carbide seals, with HNBR rubbers and synthetic graphic contact rings. A product of the highest quality for an optimal water pump performance.

Thanks to their innovative design and accompanied by a quality coolant, these seals completely prevent leakage and the result is a long service life for the water pump.

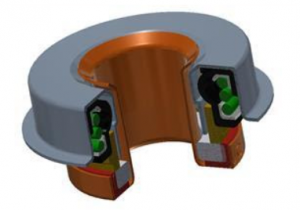

Dynamic seal components are:

- Hard carbon

- Silicon carbide seals

- Spring stainless steel

- Rubbers (NBR and HBNR)

- Stain steel housing (fixed)

- Stain steel tube (free)

State-of-the-art materials characterized by high hardness, low thermal expansion, high rigidity and good resistance to wear.

The Silicon carbide seals are made up of two differentiated parts, one of which is fixed to the casing and the other rotates along the bearing axis. All this in a single piece that is mounted independently of the turbine using a device that ensures precise height adjustment characteristics and maintaining its resistance.

Keep reading: 3 reasons to replace both the timing belt and the water pump at the same time

The silicon carbide seals revolution

Silicon carbide (SiC) is a material with properties of great hardness, similar to a diamond, which make it ideal for use in component manufacturing processes that are exposed to extreme temperatures, voltage and frequency.

This semiconductor and refractory material resists abrasion and wear which gives multiple benefits such as high thermal conductivity, high mechanical resistance and low coefficient of friction.

As a result, you get a longer lifespan for your water pump.

Dolz, innovating since 1934

Beyond supplying the most experienced water pumps on the market, Dolz ensures the tightness of all its manufactured parts through a rigorous process that calibrates and detects any possible leaks.

By staying ahead of the aftermarket industry, we fulfil our strong commitment of evolving in terms of design, manufacture and delivery, giving our clients the best solutions and providing excellent quality, service and innovation. Got questions? We will be happy to help you!